305, Building 62, Juyuanzhou Industrial Park, No. 618 Jinshan Avenue, Fuzhou, Fujian, China

Our professional team, composed of sports equipment engineers, material specialists, and former pro athletes, is dedicated to innovating high-performance gear for beach tennis, padel, and pickleball. Every product in our lineup—from lightweight pickleball paddles to durable padel rackets and weather-resistant beach tennis gear—adheres strictly to USAPA (USA Pickleball Association) standards, ensuring they meet the rigorous requirements for official tournaments and competitive play.

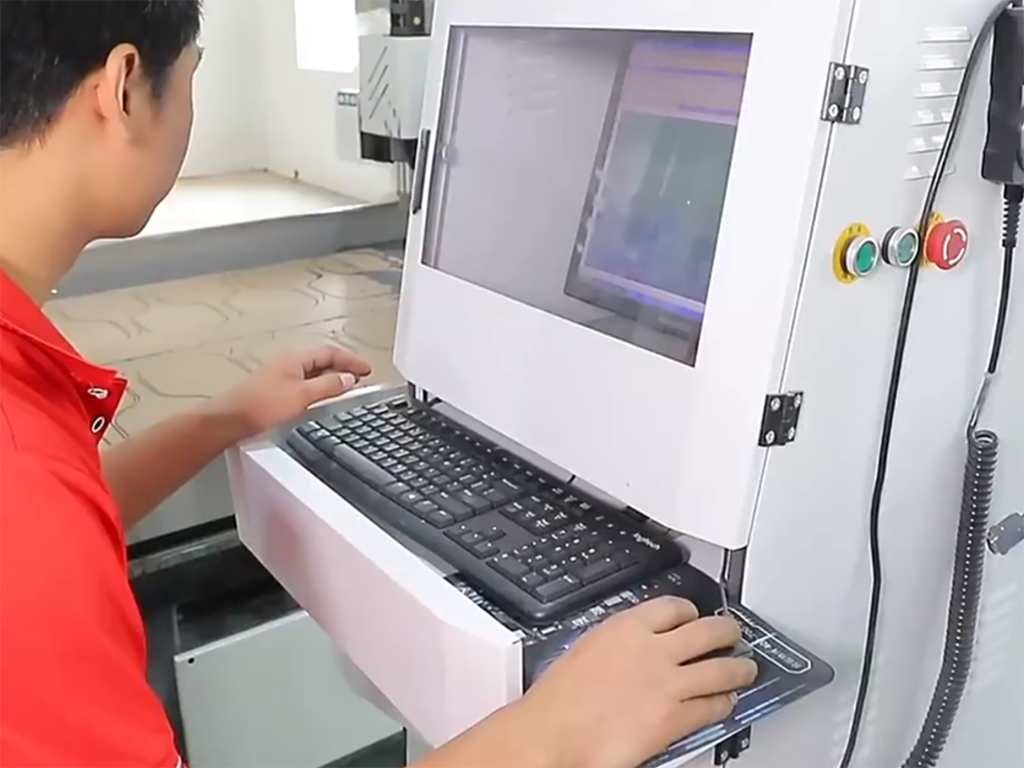

We specialize in both hot and cold pressing processes, utilizing premium materials such as high-grade glass fiber and carbon fiber—available in specifications ranging from 3K to 18K, including T700 grade, to meet diverse strength, weight, and durability requirements. Every step of production is governed by a rigorous quality control system: from raw material inspection and in-process testing to final product evaluation, ensuring consistent performance and adherence to industry standards for your sports equipment, industrial components, or custom parts.

Prior to production, we first verify that raw materials meet strict standards. During manufacturing, we conduct continuous checks to ensure products adhere to quality benchmarks. Once production wraps up, finished products undergo comprehensive inspections—including visual checks, dimensional measurements, functional tests, and performance evaluations—to guarantee they meet our rigorous standards.